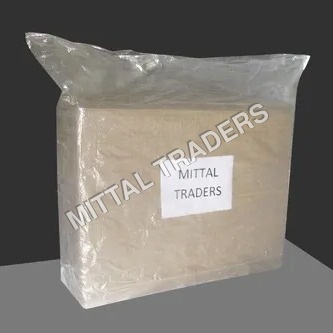

Transparent PP Woven Bag

Price 5 INR/ Piece

Transparent PP Woven Bag Specification

- Printing

- Available upon request (Flexographic/Screen) or Plain

- Material

- Polypropylene (PP)

- Bag Type

- Woven Bag

- Handles

- Without Handles

- Size

- Customizable

- Color

- Transparent

- Load Capacity

- 10 to 50 kg (depending on bag size)

- Customized

- Yes

- Feature

- High Strength, Durable, Moisture Proof, Recyclable

- Thickness

- 55 to 120 GSM (custom per requirement)

- Shape

- Rectangular

- Sealing & Handle Type

- Heat Sealable, Stitched Bottom

- Surface Finish

- Smooth

- Usage

- Agriculture, Food Packaging, Fertilizer, Industrial Products

- Lamination

- Available (on request)

- Transparency Level

- Semi-Transparent to Transparent

- Eco-Friendly

- Yes

- Tear Resistance

- High

- Moisture Barrier

- Yes

Transparent PP Woven Bag Trade Information

- Minimum Order Quantity

- 200 Pieces

- FOB Port

- New Delhi

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 100000 Pieces Per Month

- Delivery Time

- 2 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Transparent PP Woven Bag

- Material: Constructed from transparent polypropylene (PP) woven fabric, known for its durability and resistance to tearing.

- Visibility: Clear design allows easy identification of contents without needing to open the bag, making it suitable for retail display and storage.

- Strength: Offers reliable protection for items inside, ensuring they remain secure during handling and transportation.

- Versatility: Ideal for a wide range of applications including packaging of garments, hardware, toys, and agricultural products.

- Customization: Can be tailored in various sizes and optionally printed with logos or labels to enhance brand visibility.

Versatile Applications Across Industries

Whether youre in agriculture, food processing, fertilizer production, or industrial manufacturing, these transparent PP woven bags are engineered to cater to a wide spectrum of packaging needs. Their semi-transparent to transparent structure makes content identification effortless, streamlining logistics and inventory management. Built to accommodate a variety of products, these bags ensure safety and convenience for both distributors and end users.

Customizable Strength and Secure Packaging

With a customizable thickness from 55 to 120 GSM, our bags can be tailored to your requirements. The high tear resistance, heat-sealable sealing, and stitched bottoms fortify each bag, providing strong protection during handling and transit. The option for lamination and personalized printing further enhances product appeal and safety, making these bags a reliable choice for packaging sensitive goods.

FAQs of Transparent PP Woven Bag:

Q: How are transparent PP woven bags typically used in various industries?

A: Transparent PP woven bags are widely used to package agricultural produce, food items, fertilizers, and various industrial products. Their moisture-proof and durable construction protects contents during storage and transport, while the transparency allows for quick product identification.Q: What customization options are available for these bags?

A: The bags can be customized by size, thickness (55 to 120 GSM), level of lamination, and type of printing (Flexographic/Screen or plain). You can also select the desired load capacity and request other specifications to match unique packaging requirements.Q: When should I request lamination or printing on PP woven bags?

A: Lamination is recommended when extra moisture or dust protection is needed. Printing is beneficial if you want branding, labeling, or product information displayed on the packaging. Both options are available upon request to enhance the functionality and visual appeal.Q: Where can these PP woven bags be sourced in India?

A: These bags are distributed, manufactured, supplied, and traded by certified providers across India. Orders can be customized and delivered locally or regionally, ensuring timely supply for your packaging needs.Q: What is the manufacturing process for these woven bags?

A: The bags are produced by weaving polypropylene strips into a robust fabric, followed by cutting to size, adding a stitched bottom, and, if required, applying lamination or printing. The final product offers high strength, tear resistance, and secure sealing options.Q: How does the moisture barrier benefit the packaged goods?

A: The integrated moisture barrier protects against humidity and external moisture, preserving the freshness and integrity of the contents. This feature is particularly valuable for perishable and sensitive products like food grains and fertilizers.Q: What are the advantages of using eco-friendly PP woven bags?

A: Eco-friendly PP woven bags are recyclable and reusable, reducing environmental impact. They offer high durability and strength, minimizing the need for additional packaging materials, and contribute to sustainable business practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PP Woven Fabric Bag Category

Coloured Fabric Bag

Price 5 INR / Piece

Minimum Order Quantity : 200 Pieces

Load Capacity : 10 Kilograms (kg)

Handles : Other

Material : Highquality Polypropylene (PP)

Bag Type : Flat, opentop

Transparent PP Bag

Price 5 INR / Piece

Minimum Order Quantity : 200 Pieces

Load Capacity : Suitable for lightweight to mediumweight items Kilograms (kg)

Handles : Other

Material : Highquality Polypropylene (PP)

Bag Type : Flat, opentop

PP Woven Fabric Bag

Price 5 INR / Piece

Minimum Order Quantity : 200 Pieces

Load Capacity : 2050 kg

Handles : Other, With Handles

Material : PP (Polypropylene) Woven Fabric

Bag Type : Woven Fabric Bag

White Laminated PP Woven Bag

Price 5 INR / Piece

Minimum Order Quantity : 200 Pieces

Load Capacity : 2550 kg (Depending on size & GSM)

Handles : Other, No (Optional on request)

Material : Polypropylene (PP)

Bag Type : Laminated Woven Sack

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS